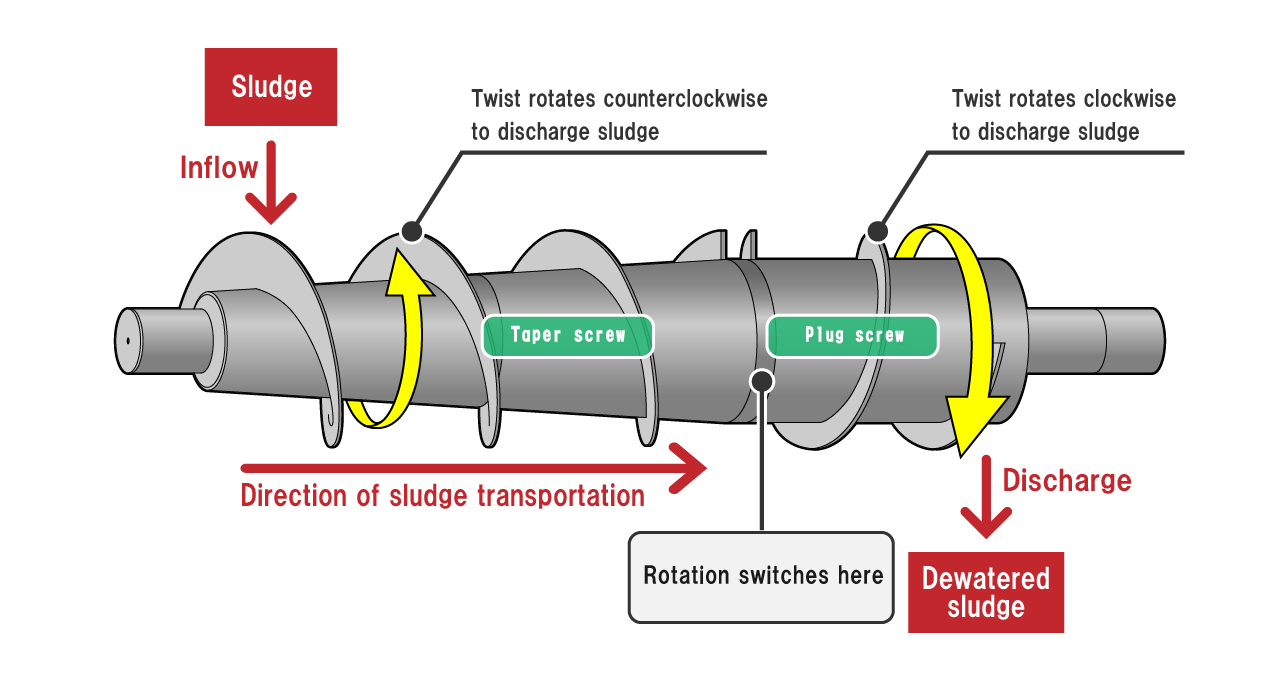

Two-stage screw shaft mechanism enables even higher dehydration rate

◆Stable Operation

A thorough squeeze of sludge is achieved by fine adjustment to the sludge properties. By eliminating a back pressure plate, leakage and blockage of dehydrated(dewatered) cake hardly occur.

◆Easy Operation

Change of sludge properties can be easily dealt with by adjusting the frequency of two motors. The rear stage shaft (plug screw) can forcibly discharge dehydrated cake.

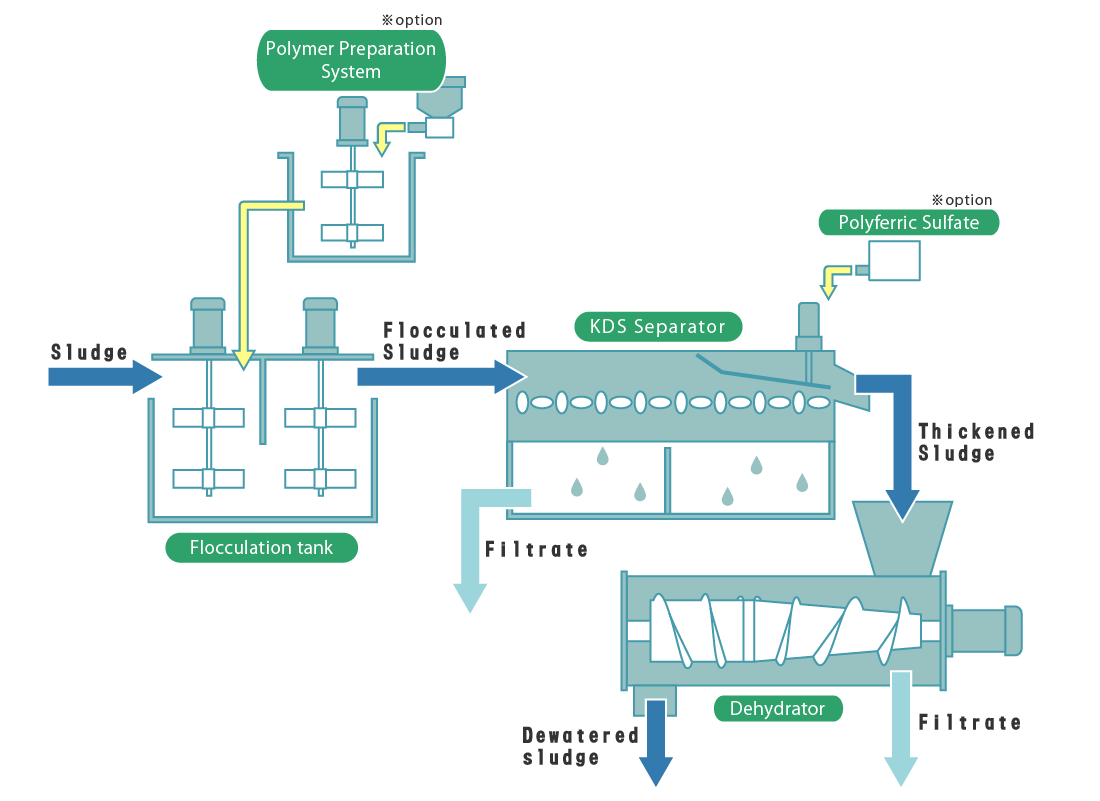

◆High thickening efficiency

By using KDS Separator for pre-thickening, the amount of sludge recovery, the treatment capacity and the dewatering ability are greatly increased. Besides, the amount of backwash water is reduced.

| Chemical Solution | Mixed Raw Sludge | Digested Sludge | Oxidation Ditch Excess Sludge | |

|---|---|---|---|---|

| Coax Reverse Rotation Screw Press | 1 solution | 34% | 17% | |

| 2 solutions | 41% | 28% | 24% | |

| Shaft Sliding Type Screw Press | 1 solution | 23% | 17% | |

| 2 solutions | 35% | 20% | ||

| Belt Press | 1 solution | 17% |

*2 solutions (Polymer Flocculant + Polyferric Sulphate)

| Models | DBSP 300-800 (Screen Diameter) KDS Separator 300-1200 (Filtration Passage Width) |

|---|---|

| Accessories | Flocculation Tank Electrical Control Panel |

| Options | Polymer Preparation System Polyferric Sulphate Feeder |