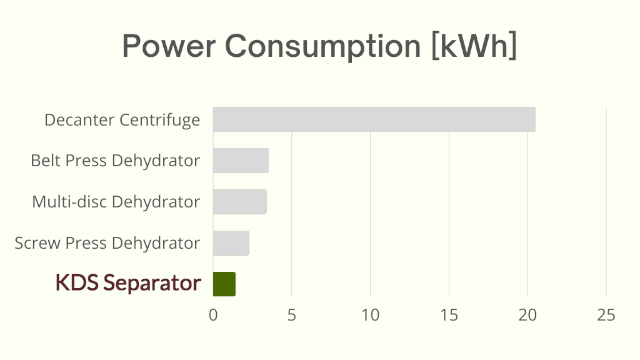

Low power consumption

Our unique oval-plate units rotate slowly (12-16 revolutions per minute).

Therefore, KDS separator operates on low power.

Compared to decanter centrifuges, power consumption is approximately 1/15. (KDS Separator : treatment capacity 40kgDS/hr model)