Case Study : Digested Sludge Dewatering at Biogas Plant

Sludge treatment is a critical challenge for biogas plants, where food waste is transformed into renewable energy. The resulting digested sludge/digestate – a byproduct of biogas production – must be dewatered efficiently to reduce waste and enable reuse.

In this case study, we explore how Kendensha’s KDS Dewatering System revolutionised wastewater treatment at a biogas plant.

Why Sludge Dewatering Matters

Biogas plants convert organic waste into energy, but the leftover sludge can be tricky to manage. Without proper dewatering, it is costly to dispose of and harmful to the environment. The KDS Dewatering System offers a sustainable solution, turning sludge into reusable fertiliser while minimising operational costs.

When a new biogas plant was built in July 2023, its operators chose the KDS Dewatering System after demonstration tests showed:

Unmatched efficiency: Superior solids recovery compared to competitors.

Lower costs: Reduced running and maintenance expenses.

Eco-friendly output: High-dryness sludge

System Specifications

| Facility | Biogas Plant |

|---|---|

| Wastewater/Sludge | Anaerobically digested sludge from food residue |

| KDS Products | KDS Dewatering System + Polymer Preparation System + Polyferric Sulphate Feeder |

| KDS Separator Model | Dewatering Pneumatic : SS-811DK 1.0mm |

| Power Consumption | Dewatering System : 1.75kW, Chemical Feeding System : 1.3kW (excluding pumps) |

| Installation | July, 2023 |

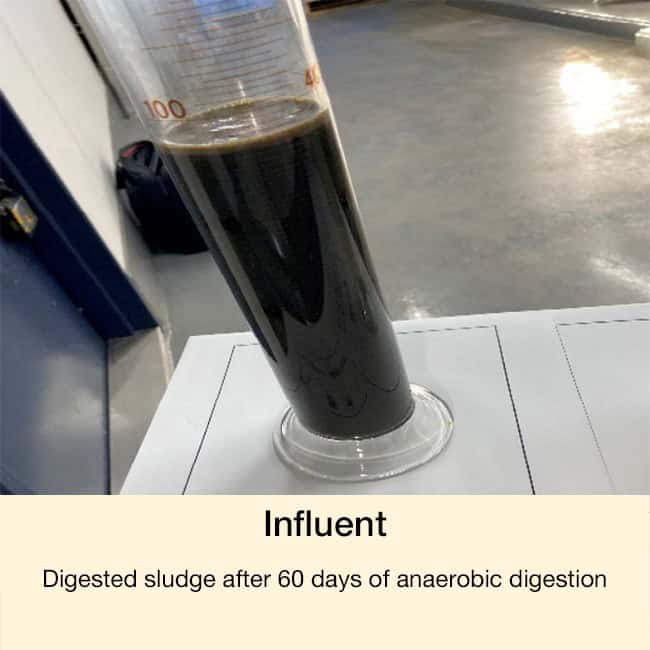

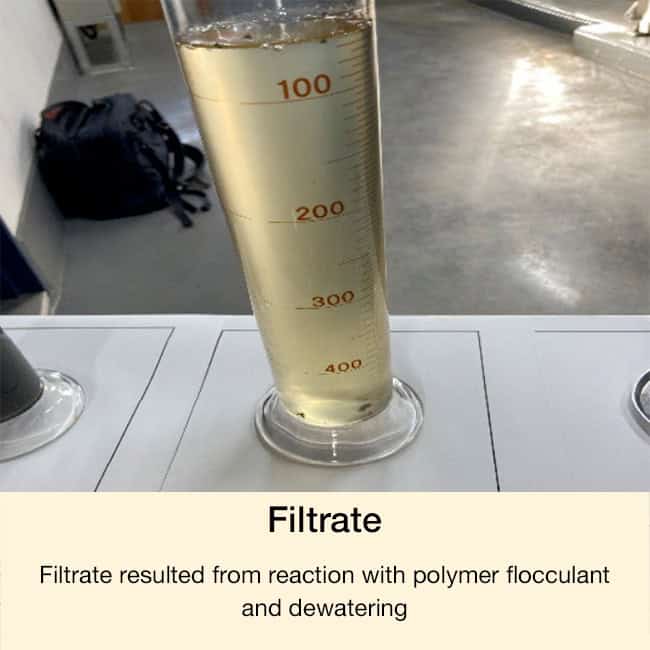

Performance Data

| Influent [mg/L] |

Filtrate [mg/L] |

|

|---|---|---|

| SS | 15,000 | 37 |

| BOD | 410 | 29 |

| COD | 4,400 | 190 |

| N-hex extract | 120 | 3.3 |

| SS Rcovery Rate | ||

|---|---|---|

| 99.8% | ||

| Discharge Cake Dryness | ||

| 25% |

Current Performance

| Flow Rate [m3/hr] |

Solids Content [%] |

Throughput [kgDS/hr] |

Powder Flocculant Dosage [mg/L of Influent] |

Operation Hours per Day |

|---|---|---|---|---|

| 2.7 | 2.5 | 68 | 750 | 8 hours |

Before & After

Customer Feedback

We anticipated 15% cake dryness, but the KDS system consistently achieves over 25%. This has slashed energy use in our sludge dryer, saving significant costs. We’ve also reduced polymer flocculant usage, making operations even more efficient.

The KDS system is a game-changer.

See the KDS System in Action

On video page, you can find various wastewater/sludge treatment with Kendensha products.

Please check!