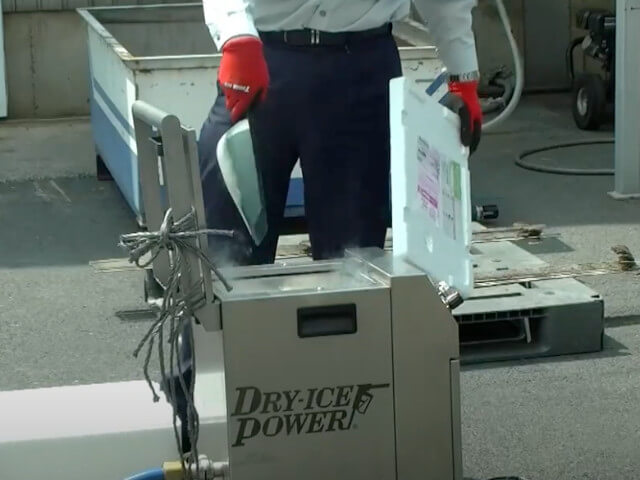

Dry Ice Blaster Demonstration

Green Tech Japan kindly visited and gave us a demonstration of a dry ice blaster (Dry Ice Power).

Here is how it worked on a KDS Separator that had been left dirty for some time after use.

What is dry ice blasting?

Dry ice (pellets) are finely crushed and sprayed with an air compressor to remove dirt. At first glance, it looks like sandblasting, but because it is dry ice, it does not scratch the object. Therefore, it is used on things which you do not want any scratch, like car bodies. Also, by spraying dry ice at such low temperatures, the difference in expansion rates between the object and the dirt is utilised to lift the dirt. Then, the dry ice enters the gap and further pulls the dirt away from the object through expansion at the time of sublimation. Naturally, after cleaning, the dry ice becomes a gas, so there is no residue. This means that no treatment is required afterwards.

This cleaning method seems to have been used overseas for some time, but has only just started to spread in Japan. For details, please look at Wikipedia page. Dry-ice blasting - Wikipedia

'Dry Ice Power' Demonstration

Dry ice pellets.

Put these into the dry ice blaster, connect the power supply and air compressor. Now, ready to go.

When sprayed on the inside of the KDS Separator casing, where the solids have dried and stuck to, the dirt was removed.

The slit bars became clean, too.

To our customers:As stated in the instruction manual, please use high-pressure water or tap water to remove adherent from the filter screen when the machine is stopped or stored for a long period of time. Drying out adherent on the filter may cause KDS Separator to malfunction. Please check Troubleshooting page, as well.

We were shown something interesting and have been considering whether we can use it in Kendensha.

Thank you to Green Tech Japan and Iwatani Corporation for taking the time and coming to visit us from such a distant place.