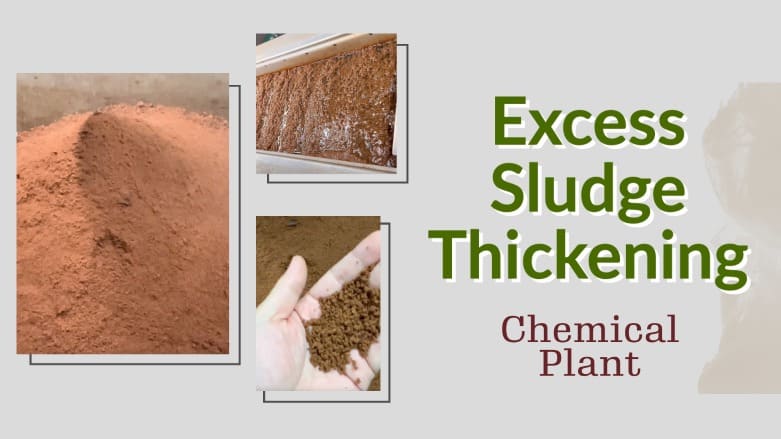

Excess Sludge Thickening at Chemical Plant

A chemical plant in Hokuriku region, KDS Separator dewatering model was installed additionally to their existing sludge dehydrating facility.

We had a brilliant outcome.

The waste disposal has been reduced by 1.7 ton / day and the treatment flow rate has been increased by 1.6 times!

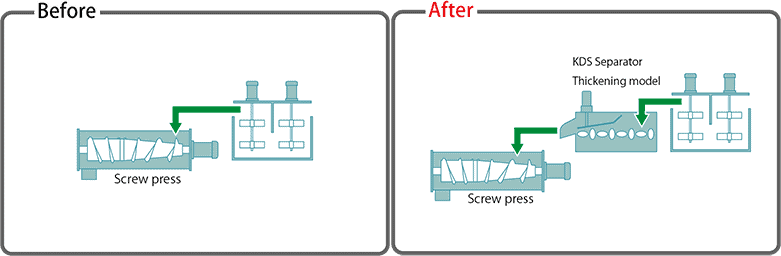

| Facility | Sludge Dehydrating Facility at Chemical Plant |

|---|---|

| Treating Wastewater | Waste Activated Sludge |

| KDS Separator Model | SS-411 |

| BEFORE Screw Press (with steam) only |

AFTER KDS Separator Thickening → Screw Press (with steam) |

|

|---|---|---|

| Treatment Capacity | 45kgDS/hr | 75kgDS/hr |

| Flow Rate | 3m3/hr | 7m3/hr |

| Thickened Cake Dryness | - | 10% |

| Dehydrated Cake Dryness | 15% | 25% |

Please play the video below!