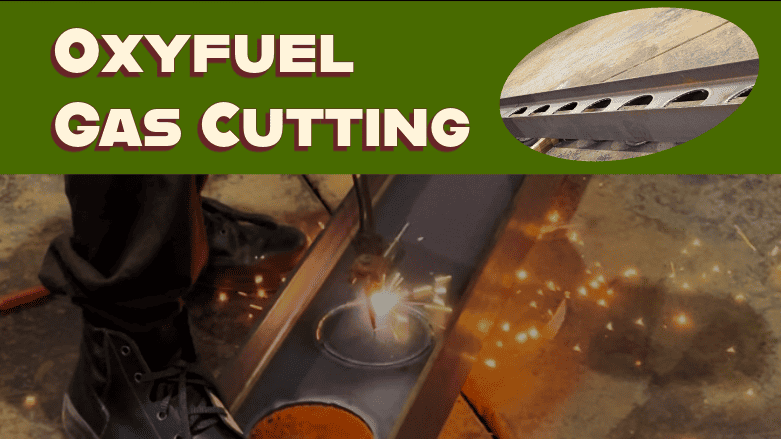

Oxyfuel Cutting!

Our CEO was doing something in a corner of the factory. He was also wearing peculiar glasses.

It is a common sight at Kendensha to see the CEO doing something quietly on his own. We had previously reported the figure of him welding silently alone on this blog. This time, he was making holes in the steel bar. It was gas cutting.

Kendensha is no exception, in recent years more and more companies introducing laser cutting, so gas cutting is not seen so often any more.

However, when it comes to processing base materials that are too large or too heavy to be set on a laser cutting machine, such as this steel bar, oxyfuel cutting still comes into its own!

Since this is a good opportunity, I am going to show you this rather nostalgic process.

Can you see the needle on the end of the torch, which forms a compass shape?

The torch is rotated around this needle without shifting its centre.

When the torch reaches the starting point, knock the inside down with a hammer. A clean round hole will appear.

Looks pretty easy, but it is probably difficult. Just as a small child cannot use a compass well, a person with little experience may not be able to cut through a regular circle. However, the CEO was muttering that he could not do it as good as he had wanted because it had been a long time since he had done this the last time.

Why he was doing this in the first place was that he wanted to lighten the steel bar.

We hope it has become a little lighter.

The CEO was a little disappointed when an employee said to him 'Wouldn't it have been easier if you had used a plasma cutting machine?'

...Anyway, If you would like to see a video of one circle being hollowed out, please play the below.