KDS System for Colloidal Silica Removal

Our client in Shizuoka Prefecture has decided to install the third KDS system, which removes colloidal silica from plant wastewater using flocculant. Thank you very much!

Some of you may have heard the term 'colloidal silica' for the first time. What this substance is used for is the polishing of semiconductor silicon and glass. Semiconductors are essential components in products necessary in our everyday life, ranging from computer CPUs to household appliances such as refrigerators. Therefore, colloidal silica, which is used in the manufacturing process of those products, is also an indispensable substance for us.

Due to the increased production of semiconductor-related products, the client has decided to expand their KDS systems in order to increase sludge treatment capacity.

Characteristics of colloidal silica

Colloidal silica is made up of silica colloidal particles dispersed in a liquid such as water and its transparency varies according to the size of the colloidal particles. This is due to Rayleigh scattering, which occurs when light strikes particles with a particle diameter smaller than the light wavelength. The larger the particle size, the stronger the scattering intensity, so that the liquid appears to the naked eye to be more white and more turbid.

In colloidal silica, particles with a particle diameter of 30 nm or less are said to have the highest scattering intensity in the sub-micron range and the whiteness is the strongest, and the liquid becomes cloudy when the particle diameter exceeds 30 nm. On the other hand, with particle diameters of 30 nm or less, the smaller the particle diameter, the closer to transparency the liquid becomes.

In short, they are "pollutants that cannot be seen visually".

Mainly used in precision abrasives and CMP (chemical mechanical planarisation) applications in the semiconductor manufacturing process, it is contained in wastewater and requires solid-liquid separation.

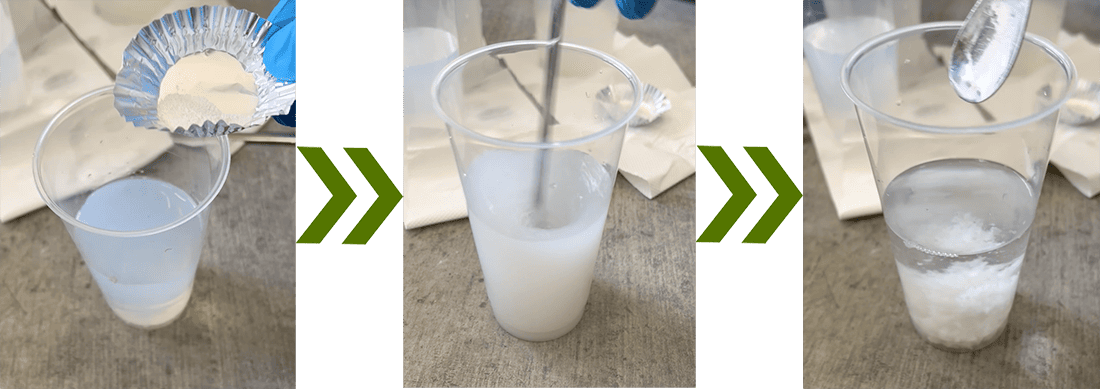

Video

Kendensha's flocculant 'AquaSaver2000' is used.

Flow Rate:3-3.5m3/hr(20-25㎏DS/hr)

On video page, you can find various wastewater/sludge treatment videos.

Please check!