Reducing Sludge Cake by Half!

Excess sludge and digested sludge consisting of highly hydrophilic fine particles are extremely difficult to dewater.

When mechanically dewatered by centrifugal, pressurised (squeezed) or other means, their water content is typically 80-85% (15 - 20% dryness).

It seems to be squeezable, but it is not...

If we could dewater it further, the amount of sludge cake would be reduced... People in the wastewater treatment industry think about this all the time.

A quiz here, out of the blue.

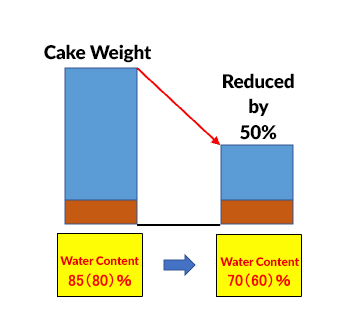

If you could reduce the water content of each of the following dewatered cakes, what do you think the weight of them would be?

- Dewatered cake with water content 85% to 70% (Dryness from 15% to 30%)

- Dewatered cake with water content 80% to 60% (Dryness from 20% to 40%)

???

Answer

A half (50%)!

As you can see, the water content is very important.

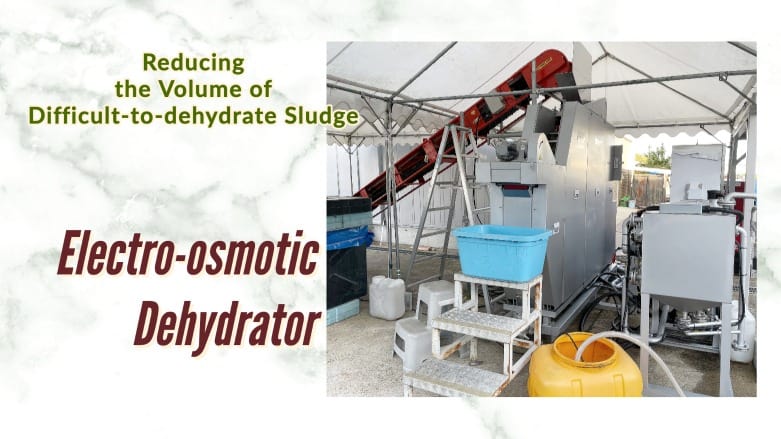

Electro-osmotic Dehydrator

Kendensha is developing a new product that combines KDS Separator and a dehydrator using the electro-osmosis principle as a unit for Japanese domestic market.

This is a brief explanation of dewatering using electro-osmosis, one of the well-known dewatering methods in the wastewater treatment industry.

Like our KDS Separator, the first thing that comes to mind when you think of dewatering methods is pressing or centrifugal separation. In everyday life, we use these principles. For example, squeezing wet towels (pressing) or in the dehydration process of washing machines (centrifugal separation). However, such methods have their limitations when trying to dewater highly hydrophilic particulate sludge. This is where the electro-osmosis principle is used to further reduce the water content and volume of the sludge.

When DC power is passed through the sludge, the negatively charged sludge collects on the positive side and the positively charged moisture on the negative side. It is something of a mystery (a moment I wish I had studied seriously when I was a student). You can pick up a technical book for more details. Anyhow, this phenomenon can be used to dehydrate sludge/wastewater efficiently.

In mid-December, an operational test was conducted in cold, snowy conditions.

The test was carried out on excess sludge from a local food processing plant.

Initially, the dewatered cake had a water content of approximately 79%. As a result of electro-osmosis dehydration, the water content dropped to approximately 59% and the weight was successfully halved.

Water Content 79% (Dryness : 21%)

Water Content 59% (Dryness : 41%)

We are working hard to develop this system so that it can be delivered to our customers as soon as possible.