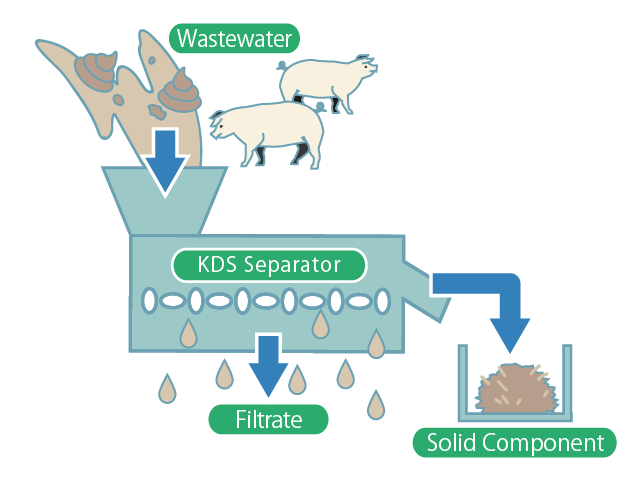

Versatile Wastewater Treatment Device

- Solid-liquid Separation / Sludge Thickening

A solid-liquid separator is used for various purposes, such as industrial wastewater/livestock wastewater treatment, residue removal from industrial wastewater and sludge thickening. One of the problems that conventional machines have is that their filter screens get clogged easily. Cost and labour are required to remove the clogging. We developed the cutting-edge mechanism with a unique self-cleaning function. The filter does not clog without backwash water. KDS separator enables reduction in installation cost, life-cycle cost. Besides, the footprint is smaller.

- Sludge Dewatering

KDS separator works as an efficent sludge dewatering device, as well. The original pressurization mechanism reduces water content and the amount of discharge. Besides, the discharged cake has been composted or utilized as cement raw material. This contributes to 3R(Reduce, Reuse, Recycle).

![]()

etc.

![]()

etc.

![]()

etc.

Please contact us for more applications and details.

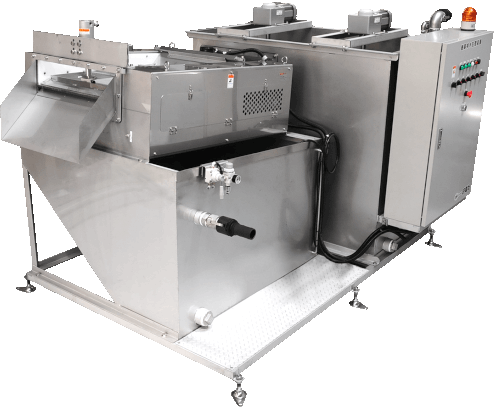

Installation

ADVANTAGE.001-1

KDS separator does not require a wide space and its noise and vibration is very little. Therefore, it is possible to design and install in a client's existing space.

Operation

ADVANTAGE.002-1

Kendensha's unique 'self-cleaning' mechanism prevents clogging on the screen, so backwash is not required. Treatment capacity reduction due to clogging does not occur. In short, continuous and stable operation is possible.

By our original self-cleaning mechanism, backwash is not needed during operation. It reduces water consumption and is environmentally friendly, as well.

KDS separator is able to be driven by a small motor because it is designed not to put a heavy load on it.

Since the motor is small, its noise and vibration is low comparing to machines with large motors mounted. The power consumption is reduced to 1/10.

Waste treatment

ADVANTAGE.003-1

Variations in sludge properties are accommodated by adjusting the rotational speed of the oval-plate units and the pressure of the pressure plate. Complex adjustments are not required.

For example, if your priority is treatment capacity, increase the rotational speed of the oval-plates and reduce the pressure of the plate to improve it.

On the contrary, if you want high dryness of discharge cake, you can reduce the water content by slowing down the oval-plate units' rotation and increasing the pressure of the plate.

When the sludge properties are such that pressurisation causes a huge amount of solids to leak into the filtrate (e.g. containing quite an amount of oil), the clarity of the filtrate can be improved by reducing the pressure of the plate.An adjustable pressure plate, attached at the top of the filter screen, dewaters sludge and gradually reduces the volume of it. Dewatering ability has been improved by adjusting the speed of oval-plate rotation and the plate pressure according to the sludge properties.

KDS Separators are in use as a solid-liquid separator or a sludge dewatering device in various fields.

Maintenance

ADVANTAGE.004-1

Consumable parts are replaced by exchanging a whole module. This makes quick restoration possible. By standardizing consumable parts, the supply is stabilized and the cost of maintenance is reduced.

In case of malfunction, please check with Troubleshooting and contact us if the problem is not solved.

| MODEL | Nominal Treatment Width [mm] |

Number of Oval Plate Rows | Motor [kw] |

Sludge Treatment Capacity※ [kgDS/hr] (Clean Water Conversion Flow Rate:m3/hr) |

Sludge Flow Rate for Reference (the concentration of 1%) [m3/hr] |

|---|---|---|---|---|---|

| SS-2.56 | 236 | 6 | 0.1 | 20 (8) | 2 |

| SS-312 | 280 | 12 | 0.2 | 45 (23) | 4.5 |

| SS-412 | 380 | 12 | 0.2 | 55 (30) | 5.5 |

| SS-512 | 480 | 12 | 0.2 | 80 (38) | 8 |

| SS-612 | 580 | 12 | 0.4 | 100 (45) | 10 |

| SS-616 | 580 | 16 | 0.4 | 130 (60) | 13 |

| SS-812 | 780 | 12 | 0.75 | 200 (98) | 20 |

| SS-912 | 880 | 12 | 0.75 | 230 (107) | 23 |

| SS-1212 | 1180 | 12 | 0.75 | 300 (144) | 30 |

Standard Model : 1.0mm gap, three-phase motor

Please Note :

- Treatment Capacity is for reference and differs depending on the concentration and the properties of wastewater.

- Electric Capacity is for reference and may change depending on the specifications and the properties of wastewater.

Please contact us for other special specifications ( e.g. cleaning nozzles, motor coatings ).

| MODEL | A [mm] |

B [mm] |

C [mm] |

D [mm] |

E [mm] |

F [mm] |

G [mm] |

H [mm] |

|---|---|---|---|---|---|---|---|---|

| SS-2.56 | (494) | 243 | (617) | (581) | (42) | (9) | 174 | (191) |

| SS-312 | 612 | 300 | (1364) | (1314) | (164) | (8) | 400 | |

| SS-412 | 712 | 400 | (1364) | (1314) | (164) | (8) | 400 | |

| SS-512 | 812 | 500 | (1364) | (1314) | (164) | (8) | 400 | |

| SS-612 | 912 | 600 | (1364) | (1314) | (164) | (8) | 400 | |

| SS-616 | 912 | 600 | (1697) | (1647) | (164) | (8) | 400 | |

| SS-812 | ※(1160) | 800 | (1680) | (1644) | (144) | (8) | 550 | |

| SS-912 | ※(1260) | 900 | (1680) | (1644) | (144) | (8) | 550 | |

| SS-1212 | ※(1560) | 1200 | (1680) | (1644) | (144) | (8) | 550 |

Click a model to download the outline drawing

Please Note : The measurement is from one end to the other of the cover.

The motor specifications will change in accordance with the electric supply and the local regulations.

Please feel free to contact us. We will suggest a total solution including KDS Separator dewatering model, the selection of flocculants and automatic polymer preparation system.